circuit board components identification pdf

Identifying circuit board components is crucial for electronics repair, design, and manufacturing․ It involves recognizing parts like resistors, capacitors, and ICs, ensuring proper functionality and compatibility․ Accurate identification helps troubleshoot issues, prevent component failures, and optimize PCB designs․ With the rise of compact packages like BGA and surface-mount devices, advanced techniques and tools are essential for precise identification and soldering․ This guide explores methods, challenges, and best practices for effective component recognition in modern electronics․

1․1 Definition and Purpose of Circuit Board Components

Circuit board components are the building blocks of electronic circuits, mounted on a printed circuit board (PCB) to perform specific functions․ These components, such as resistors, capacitors, and integrated circuits (ICs), are classified into active, passive, and electromechanical categories․ Their purpose is to process, store, or transmit electrical signals, enabling devices to operate efficiently․ Components are designed to meet precise specifications, ensuring reliability and performance․ In manufacturing, companies like Huawei have redesigned circuit boards, substituting over 13,000 components to maintain functionality and adapt to supply chain challenges․ Accurate identification of these parts is critical for troubleshooting, repair, and design optimization, as incorrect components can lead to system failures or reduced efficiency․

1․2 Importance of Component Identification in Electronics

Accurate identification of circuit board components is essential for ensuring proper functionality, reliability, and safety in electronic devices․ Misidentification can lead to system failures, reduced performance, or even safety hazards․ Component identification is critical for troubleshooting, repair, and design optimization, enabling engineers to verify compatibility and specifications․ In industries like telecommunications, companies such as Huawei have emphasized component identification to adapt to supply chain challenges, redesigning circuit boards and substituting thousands of components․ This process ensures operational continuity and minimizes the risk of component obsolescence․ Effective identification also aids in counterfeit detection and quality control, ensuring that devices meet regulatory and performance standards․ As electronics grow more complex, precise component identification becomes a cornerstone of innovation and reliability․

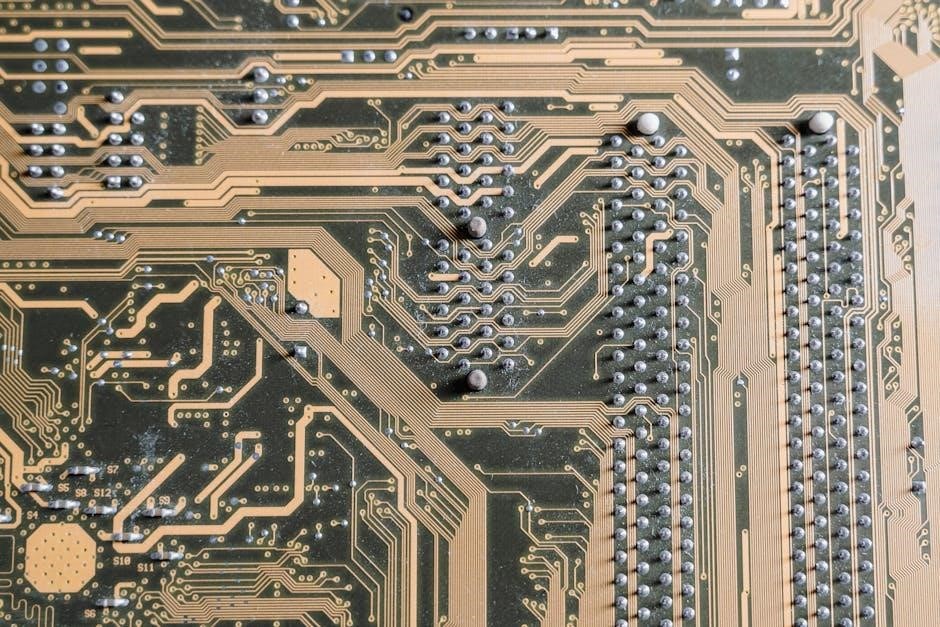

1․3 Evolution of Circuit Board Components Over Time

The evolution of circuit board components reflects advancements in technology and manufacturing․ Early components were bulky and limited in functionality, but modern components are smaller, more efficient, and integrated․ Through-hole components, once dominant, have largely been replaced by surface-mount devices (SMDs) and ball grid arrays (BGAs) for compactness and performance․ This shift has enabled miniaturization of electronics and improved reliability․ Companies like Huawei have embraced this evolution, redesigning circuit boards to accommodate advanced components and meet growing demands․ The rise of semiconductor innovations and packaging techniques has driven this transformation, ensuring faster, more powerful, and energy-efficient devices․ This evolution underscores the industry’s adaptability and continuous pursuit of innovation in component design and functionality․

Types of Circuit Board Components

Circuit boards consist of passive, active, and electromechanical components․ Passive components include resistors, capacitors, and inductors, while active components comprise diodes, transistors, and ICs․ Electromechanical parts like switches and connectors enable interaction and connectivity․

2․1 Passive Components (Resistors, Capacitors, Inductors)

Passive components are essential in circuit boards as they do not require an external power source to operate․ Resistors, capacitors, and inductors are the primary types․ Resistors oppose the flow of electric current, while capacitors store energy in an electric field․ Inductors store energy in a magnetic field and are often used to filter or regulate voltage․ These components are critical for voltage regulation, signal filtering, and energy storage in circuits․ Their values, such as resistance (ohms), capacitance (farads), and inductance (henrys), are specified to ensure proper circuit functionality․ Passive components are fundamental in both analog and digital circuits, enabling basic operations like voltage division, filtering, and impedance matching․

2․2 Active Components (Diodes, Transistors, ICs)

Active components are essential for amplifying, switching, or processing electrical signals in circuit boards․ Diodes allow current to flow in one direction while blocking it in the other, often used for rectification․ Transistors act as switches or amplifiers, controlling the flow of current based on input signals․ Integrated Circuits (ICs) combine multiple transistors and other components into a single chip, enabling complex functionalities like processing, memory storage, and communication․ These components are vital for powering modern electronics, from simple circuits to advanced computing systems․ Their ability to actively manipulate electrical signals makes them indispensable in achieving the dynamic and intelligent operation of electronic devices․

2․3 Electromechanical Components (Switches, Relays, Connectors)

Electromechanical components bridge electrical and mechanical functionalities, enabling interaction between circuits and physical systems․ Switches control current flow, acting as on/off gatekeepers․ Relays use electrical signals to activate mechanical switches, safely controlling high-power devices․ Connectors provide secure connections between PCBs or external devices, ensuring reliable signal transfer․ These components are vital for system control, protection, and scalability․ Switches allow user input, while relays protect circuits from overcurrent․ Connectors simplify maintenance and upgrades by enabling modular designs․ Together, they enhance functionality, durability, and usability in electronic systems, making them indispensable in modern circuit board design․

Component Identification Methods

Identifying components involves visual inspection, datasheets, and measurement tools like multimeters and oscilloscopes․ These methods ensure accurate recognition of resistors, capacitors, ICs, and connectors, maintaining functionality and reliability․

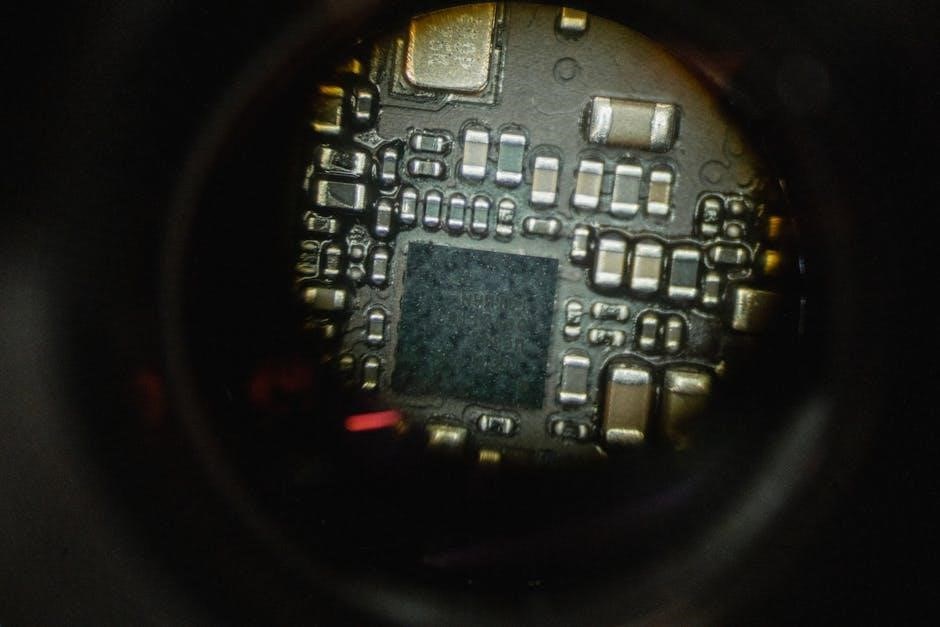

3․1 Visual Inspection and Labeling

Visual inspection is a fundamental method for identifying circuit board components․ It involves examining the physical characteristics of components, such as color, shape, and labeling, to determine their function․ For example, resistors can often be identified by their distinct color bands, while capacitors may have markings indicating their capacitance and voltage ratings․ Integrated circuits (ICs) typically have part numbers printed on their packages, which can be cross-referenced with datasheets for precise identification․ Labels on the circuit board itself, such as component designators (e․g․, R1, C2), provide additional clues․ Proper labeling ensures traceability and simplifies the troubleshooting process․ However, the miniaturization of components, such as surface-mount devices (SMDs), can make visual inspection challenging without magnification tools․

3․2 Using Datasheets for Component Identification

Datasheets are essential documents that provide detailed information about electronic components, enabling accurate identification and specification verification․ They typically include part numbers, package types, pin configurations, and electrical characteristics․ For instance, a resistor’s datasheet will specify its resistance value, tolerance, and power rating, while an IC’s datasheet will detail its functional blocks, input/output pins, and operating conditions․ By cross-referencing the component’s markings with the datasheet, engineers can confirm its identity and ensure compatibility with the circuit design․ Datasheets also help in verifying the authenticity of components, reducing the risk of counterfeit parts․ This resource is critical for both designing new PCBs and troubleshooting existing ones, ensuring reliable performance and compliance with design standards․

3․3 Measurement Techniques (Multimeter, Oscilloscope)

Measurement techniques are critical for identifying circuit board components, especially when visual inspection or datasheets are insufficient․ A multimeter is a versatile tool for measuring electrical properties such as voltage, current, resistance, and capacitance․ It helps verify the functionality of components like resistors, capacitors, and diodes․ For example, measuring resistance can confirm a resistor’s value, while diode testing can identify its forward and reverse bias characteristics․ An oscilloscope is used to analyze signal waveforms, which is essential for understanding the behavior of active components like transistors or ICs in a live circuit․ These tools enable engineers to troubleshoot and identify components accurately, ensuring the circuit operates as intended․ They are indispensable for both prototyping and repair processes in electronics․

Challenges in Circuit Board Component Identification

Identifying circuit board components is challenging due to miniaturization, complex soldering, and unclear labeling․ This complicates troubleshooting and repair, especially with modern, densely populated PCBs․

4․1 Component Obsolescence and Availability Issues

Component obsolescence poses significant challenges in circuit board identification, as outdated parts become discontinued or hard to source․ This issue is exacerbated by rapid technological advancements, leading to frequent component replacements․ Engineers often face difficulties in identifying suitable substitutes, especially for legacy systems․ Availability issues further complicate the process, as lead times for certain components can extend, delaying repairs or production․ Industries like aerospace and automotive, which rely on long-life systems, are particularly affected․ Additionally, the rise of counterfeit parts in the supply chain due to high demand for obsolete components adds another layer of complexity․ Proper documentation and inventory management are critical to mitigating these challenges and ensuring continuity in electronics manufacturing and maintenance․

4․2 Counterfeit Components and Their Impact

Counterfeit components pose a significant threat to the reliability and functionality of circuit boards․ These unauthorized parts, often indistinguishable from genuine ones, infiltrate the supply chain through third-party vendors or online marketplaces․ Their use can lead to premature failure, safety hazards, and financial losses․ In critical industries like aerospace and healthcare, counterfeit components can endanger lives․ Additionally, they damage a company’s reputation and may result in legal consequences․ Identifying counterfeit components requires advanced testing methods, as they often mimic authentic parts․ The rise of counterfeit electronics underscores the need for rigorous quality control and authentication processes to ensure the integrity of circuit board components and maintain trust in the electronics industry․

4․3 Miniaturization of Components (SMD, BGA)

The miniaturization of circuit board components, such as Surface Mount Devices (SMD) and Ball Grid Arrays (BGA), has revolutionized electronics by enabling smaller, lighter, and more efficient designs․ SMDs, which mount directly onto the PCB surface, offer higher density and faster signal transmission compared to through-hole components․ BGAs, with their grid of solder balls, provide excellent thermal and electrical performance, making them ideal for complex integrated circuits․ However, miniaturization introduces challenges in identification, as components become increasingly difficult to distinguish visually․ This necessitates advanced tools like X-ray inspection and automated optical systems to ensure proper placement and functionality․ The trend toward miniaturization continues to drive innovation but also complicates component identification and repair processes in modern electronics․

Tools and Resources for Component Identification

Essential tools for component identification include multimeters, oscilloscopes, and soldering stations․ Digital resources like PCB design software and online databases aid in precise component tracking and verification․

5․1 Soldering and Desoldering Tools

Soldering and desoldering tools are indispensable for circuit board component identification․ A soldering iron with adjustable temperature control is essential for safely connecting or disconnecting components․ Desoldering tools, such as solder pumps or braid, help remove excess solder without damaging the PCB․ Soldering tips of varying sizes ensure precision for different component types․ Additionally, a soldering station with a built-in stand and sponge improves safety and efficiency․ Anti-static gloves and goggles protect against electrical discharges and debris․ Flux pens or sprays can enhance solder flow for tricky joints․ These tools enable technicians to access and inspect components without causing permanent damage, making them critical for accurate identification and repair processes in electronics maintenance and troubleshooting․

5․2 PCB Design Software for Component Tracking

PCB design software plays a vital role in component tracking by providing a detailed digital representation of circuit boards․ Tools like Eagle, KiCad, and Altium allow designers to annotate components with unique identifiers, making it easier to trace and verify parts during assembly․ These programs often include libraries of standard components, ensuring consistency and accuracy․ Features like Bill of Materials (BOM) generation and automated part numbering streamline inventory management․ Additionally, real-time component tracking reduces errors and enhances collaboration among engineers․ By integrating with manufacturing processes, PCB software ensures seamless communication between design and production teams, improving overall efficiency in component identification and PCB assembly․

5․3 Online Databases and Forums for Identification

Online databases and forums are invaluable resources for identifying circuit board components․ Websites like Digi-Key, Mouser, and Octopart provide extensive databases of electronic components, allowing users to search by part numbers, specifications, or manufacturers․ Forums such as EEVblog, Reddit’s r/electronics, and Stack Overflow host communities where engineers and hobbyists share knowledge and solve identification challenges․ These platforms often include discussions on obscure or hard-to-identify components, offering practical solutions․ Additionally, platforms like SnapEDA and ComponentSearch simplify the process by enabling users to search for components based on parameters or images․ These online tools foster collaboration and provide accessible solutions for component identification, making them essential for both professionals and enthusiasts in electronics․

Case Studies in Component Identification

Case studies provide practical insights into real-world challenges and solutions in component identification, offering valuable lessons for electronics engineers and hobbyists alike․

6․1 Huawei’s Redesign of Circuit Boards and Component Substitution

Huawei faced significant challenges due to global component shortages and sanctions, necessitating the redesign of their circuit boards․ This involved identifying and substituting critical components while ensuring compatibility and performance․ The company leveraged advanced component identification techniques, such as visual inspection, datasheet analysis, and testing, to validate replacements․ Strategic collaboration with suppliers and internal engineering teams was crucial for sourcing alternatives․ The case highlights the complexity of modern PCB design and the importance of robust component tracking systems․ It also underscores the need for contingency planning in the electronics industry to mitigate supply chain disruptions and component obsolescence․ This approach ensured Huawei’s products remained competitive despite external constraints․

- Strategic component substitution to address shortages․

- Rigorous testing of alternative components․

- Collaboration with suppliers for reliable solutions․

6․2 FPGA Breakout Board Development Challenges

FPGA breakout board development presents unique challenges in component identification and integration․ Engineers must ensure compatibility between the FPGA and external components, such as I/O interfaces and power management circuits․ Signal integrity issues, like impedance mismatch and noise, complicate the design process․ Additionally, the miniaturization of FPGA packages, such as BGA types, makes manual soldering and debugging difficult․ Component selection is further strained by the need for high-speed signal routing and proper grounding․ These challenges highlight the importance of advanced tools, such as signal analyzers and PCB simulation software, to validate designs before fabrication․ Effective component identification and careful layout planning are critical to overcoming these hurdles and ensuring optimal performance․

- Signal integrity and noise management․

- Complexity of high-speed signal routing․

- Challenges with BGA package soldering․

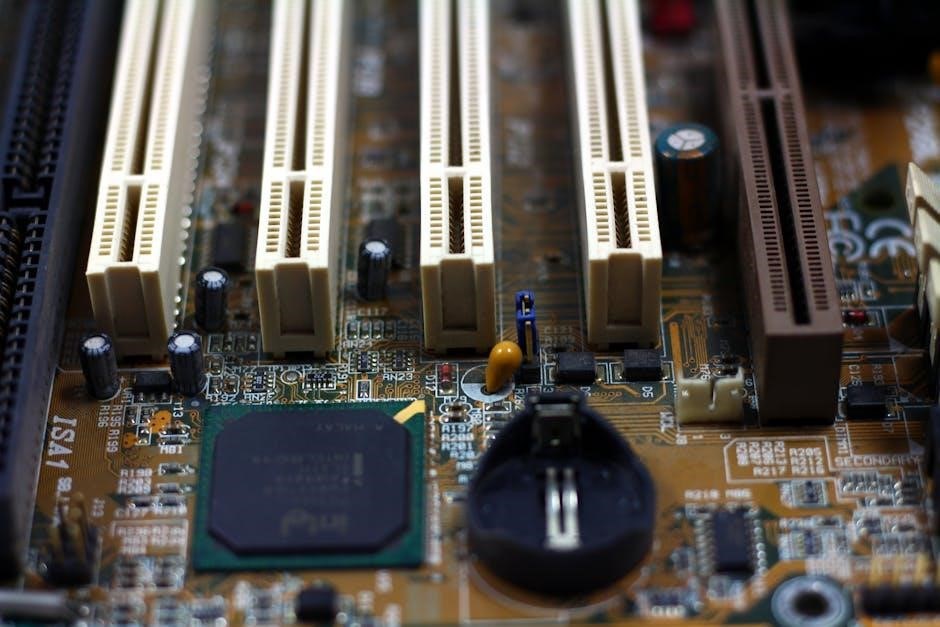

6․3 Through-Hole vs․ Surface-Mount Assembly

Through-Hole (THT) and Surface-Mount Technology (SMT) assemblies differ significantly in component identification and assembly processes․ THT components have leads that pass through the PCB, offering easier manual soldering and inspection․ In contrast, SMT components are mounted directly on the board surface, making them smaller and more densely packed․ This miniaturization enhances performance but complicates visual inspection and manual soldering․ Component identification in SMT often requires advanced tools like magnifiers or X-ray machines due to their compact size․ THT components, with larger and more accessible labels, are generally easier to identify․ The choice between THT and SMT influences design flexibility, cost, and manufacturing efficiency, with SMT being more common in modern electronics due to space and performance advantages․

- THT: Easier inspection and manual soldering․

- SMT: Smaller, denser, and harder to inspect․

- Impact on component identification methods․

Best Practices for Documenting Components

Accurate documentation ensures traceability and simplifies future repairs․ Maintain detailed records of each component, including type, value, and manufacturer․ Use standardized labeling and version-controlled databases for consistency․

- Create a centralized component library․

- Include reference designators on schematics․

- Regularly update documentation for revisions․

7․1 Creating a Comprehensive Component List

A detailed component list is essential for efficient circuit board management․ Include reference designators, manufacturer part numbers, and specifications․ Note component values, tolerances, and package types for clarity․ Organize the list alphabetically or by category for easy lookup․ Cross-reference each component with its location on the PCB to streamline troubleshooting․ Use standardized templates or BOM (Bill of Materials) tools to maintain consistency․ Include suppliers and pricing information for procurement planning․ Add notes on obsolete or hard-to-find parts to facilitate future sourcing․ Regularly update the list to reflect design changes or substitutions․ Ensure accessibility across teams by storing it in a shared database or version-controlled system․

- Reference designators (e․g․, R1, C2)․

- Manufacturer part numbers and datasheet links․

- Quantity required and package type․

- Supplier information and lead times․

7․2 Organizing Datasheets and Technical Documents

Keeping datasheets and technical documents well-organized is crucial for efficient component identification and design accuracy․ Store these files in a centralized digital repository, such as Google Drive or SharePoint, to ensure easy access․ Use clear naming conventions, like part number and version, for quick retrieval․ Maintain version control to avoid confusion and ensure the latest documents are used․ Cross-reference datasheets with component lists and schematics for seamless integration․ Regularly update the library with new or revised documents․ Use tags or folders to categorize files by component type or project․ This system reduces errors, saves time, and enhances collaboration among team members․ It also ensures compliance with industry standards and regulations․

- Centralized digital storage for accessibility․

- Version control to track updates․

- Consistent naming conventions․

7․3 Using Version Control for PCB Designs

Version control is essential for managing changes in PCB designs, ensuring design integrity and traceability․ Tools like Git enable tracking of modifications, reducing errors and simplifying collaboration․ By maintaining a clear history of design revisions, engineers can easily identify changes and revert if needed․ Assigning unique identifiers to components and layers helps track modifications․ Regular commits with descriptive messages improve clarity․ This practice is vital for identifying components, troubleshooting, and maintaining design consistency․ It also supports teamwork, preventing conflicts and ensuring all team members work on the latest version․ Implementing version control enhances efficiency and accuracy in PCB design and component identification․

- Track design changes effectively․

- Enhance collaboration and reduce errors․

- Maintain clear revision history․

Future Trends in Circuit Board Component Identification

Advancements in AI, IoT, and automation are revolutionizing component identification, enabling faster, more accurate, and scalable solutions for complex PCBs․

8․1 AI and Machine Learning in Component Recognition

AI and machine learning are transforming component recognition by enabling automated identification of circuit board components․ These technologies use advanced algorithms to analyze visual data from PCBs, enhancing accuracy and speed․ Machine learning models can be trained to recognize patterns, shapes, and labels on components, reducing human error․ AI-powered tools also support predictive maintenance by identifying faulty components before they fail․ Additionally, AI-driven systems can adapt to new component designs, making them versatile for evolving electronics․ The integration of AI in component recognition streamlines the design, manufacturing, and repair processes, ensuring higher efficiency and reliability in electronic systems․ This innovation is critical for meeting the demands of complex modern circuits and miniaturized components․

8․2 3D Printing and Custom Component Fabrication

3D printing is revolutionizing custom component fabrication by enabling the creation of complex and tailored circuit board components․ This technology allows for the rapid prototyping of unique shapes and designs, reducing production time and costs․ Conductive inks and metal-filled filaments are being used to fabricate functional components, such as resistors and antennas, directly onto PCBs․ Custom fabrication also supports the development of miniaturized components, addressing the demand for compact electronics․ While challenges like material durability and performance remain, 3D printing offers unparalleled flexibility for innovating component designs․ This approach is particularly valuable for niche applications and prototyping, enabling engineers to test and refine components quickly and efficiently․

8․3 Sustainability and Recyclable Components

The growing emphasis on sustainability is driving the development of recyclable and eco-friendly circuit board components․ Manufacturers are increasingly adopting materials and practices that minimize environmental impact, such as using biodegradable plastics and conflict-free metals․ Recyclable components reduce e-waste, a significant issue in the electronics industry․ Designing components for disassembly and reuse is becoming a priority, alongside energy-efficient production methods․ Regulations like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) are pushing the industry toward greener solutions․ As consumer demand for sustainable products rises, the electronics sector is shifting toward more responsible practices, ensuring a healthier planet while maintaining technological advancement․

Summarizing circuit board components’ evolution, we stress identification practices, challenges like miniaturization and counterfeits, and sustainability․ Proper identification ensures electronics’ reliability, safety, and efficiency, guiding future innovations responsibly․

9․1 Recap of Key Component Identification Strategies

Effective circuit board components identification relies on a combination of visual inspection, datasheet analysis, and advanced measurement tools․ Visual inspection helps recognize component types and condition, while datasheets provide detailed specifications․ Multimeters and oscilloscopes enable precise measurements to verify functionality․ Additionally, organizing components and maintaining thorough documentation ensures traceability and efficiency․ These strategies collectively enhance the accuracy and speed of identifying components, which is critical for designing, repairing, and optimizing electronic circuits․ By mastering these techniques, engineers and technicians can mitigate risks associated with component failures and ensure the reliability of electronic systems․ Proper identification practices are foundational to advancing electronics and PCB design․

9․2 The Role of Technological Advancements in Electronics

Technological advancements have revolutionized the field of electronics, particularly in circuit board component identification․ Innovations such as automated optical inspection (AOI) systems and AI-driven software enable rapid and accurate detection of components․ Machine learning algorithms improve pattern recognition, reducing human error in identifying complex or miniaturized parts․ Additionally, advancements in 3D printing and IoT integration have enhanced component tracking and quality control․ These technologies not only streamline the identification process but also address challenges like counterfeit detection and component obsolescence․ By leveraging these tools, the electronics industry achieves greater efficiency, precision, and scalability, ensuring the development of reliable and cutting-edge electronic systems․

9․3 Final Thoughts on the Importance of Component Identification

Accurate component identification is fundamental to ensuring the reliability and functionality of electronic systems․ It prevents errors, enhances safety, and guarantees that all parts work harmoniously․ Proper identification aids in troubleshooting, maintenance, and upgrading, ensuring long-term performance․ Moreover, it supports compliance with industry standards and facilitates collaboration among engineers․ As technology advances, the ability to identify components efficiently becomes crucial for innovation and sustainability․ By prioritizing precise identification, professionals can build trust in their designs and contribute to the advancement of electronics․ Ultimately, component identification is not just a technical task but a cornerstone of creating dependable and cutting-edge electronic solutions․