concrete reinforcing steel institute manual of standard practice pdf

The Concrete Reinforcing Steel Institute (CRSI) is a leading authority in the reinforced concrete construction industry, promoting best practices and standards for steel reinforcement.

CRSI publishes the Manual of Standard Practice, a comprehensive guide for engineers, contractors, and fabricators, ensuring compliance with industry standards and specifications.

As a trusted resource, CRSI’s manual covers materials, design, and construction practices, making it essential for professionals involved in reinforced concrete projects.

1.1 Overview of CRSI and Its Role in the Industry

The Concrete Reinforcing Steel Institute (CRSI) is a prominent organization dedicated to advancing the use of reinforced concrete. Established as a technical resource, CRSI promotes best practices, standards, and education within the construction industry. Its primary role includes setting guidelines for materials, design, and construction practices. CRSI serves as a vital link between producers, engineers, and contractors, ensuring compliance with industry standards. The institute’s publications, such as the Manual of Standard Practice, are widely recognized as essential resources for professionals. CRSI’s efforts focus on improving the quality, safety, and sustainability of reinforced concrete structures, making it a cornerstone of the industry;

1.2 Importance of the Manual of Standard Practice

The Manual of Standard Practice is a critical resource published by CRSI, providing detailed guidelines for the design, fabrication, and placement of reinforcing steel; It serves as a comprehensive reference for engineers, contractors, and fabricators, ensuring compliance with industry standards. The manual addresses materials specifications, bar detailing, and construction practices, offering practical solutions to common challenges. Its importance lies in its ability to promote consistency, quality, and safety in reinforced concrete construction. Regular updates ensure the manual remains aligned with the latest ASTM standards and industry advancements. As a result, it is an indispensable tool for professionals aiming to deliver durable and structurally sound concrete structures.

Key Chapters in the CRSI Manual of Standard Practice

The manual includes chapters on materials, specifications, reinforcing bar details, and welded wire reinforcement, providing essential guidance for engineers and contractors to ensure compliance with industry standards.

2.1 Materials and Specifications for Reinforcing Steel

The CRSI Manual of Standard Practice provides detailed specifications for reinforcing steel, including allowable tolerances, chemical composition, and mechanical properties. It emphasizes compliance with ASTM standards to ensure material quality and durability. The manual also covers various types of reinforcing steel, such as carbon steel, stainless steel, and epoxy-coated bars, addressing their unique properties and applications. Additionally, it outlines requirements for welded wire reinforcement, ensuring consistency and performance in construction projects. By adhering to these specifications, professionals can maintain structural integrity and meet industry standards for reinforced concrete design and construction.

2.2 Reinforcing Bar Details and Placement

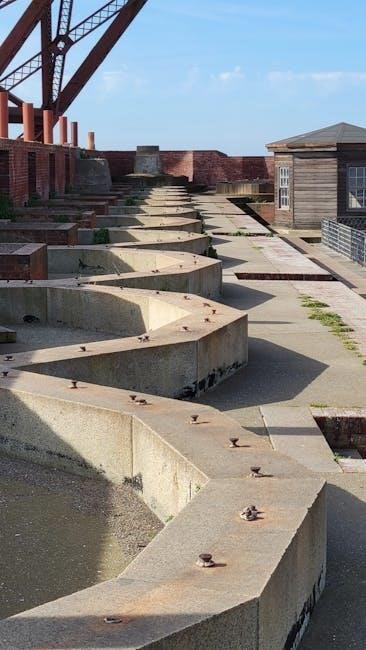

The CRSI Manual of Standard Practice provides detailed guidelines for reinforcing bar detailing and placement, ensuring proper structural performance. It covers requirements for bar spacing, cover, and alignment, as well as specific detailing for various structural elements such as beams, columns, and slabs. The manual emphasizes the importance of accurate placement to prevent structural deficiencies and ensure durability; It also includes recommendations for handling special detailing scenarios, such as curved or bent bars, and provides standards for identifying and marking reinforcement to facilitate correct installation. Adherence to these guidelines helps ensure that reinforcing steel is correctly positioned and secured within the concrete structure, meeting both design and safety standards.

Design Considerations for Reinforced Concrete

Design considerations for reinforced concrete involve strength, durability, and serviceability, guided by CRSI’s Manual of Standard Practice, ensuring optimal structural performance and material efficiency.

3.1 Development Lengths and Splice Requirements

Development lengths and splice requirements are critical for ensuring reinforcing steel effectively transfers stresses to the concrete. The CRSI Manual provides detailed guidelines for these calculations, considering factors like bar size, concrete strength, and environmental conditions. Proper development lengths prevent bond failure, while splices must maintain structural continuity. The manual outlines different splice types, such as lap splices and mechanical connections, and specifies minimum requirements to ensure reliability. These standards are essential for achieving durable and safe reinforced concrete structures, adhering to industry best practices and compliance with ASTM standards. Adherence to these specifications helps prevent premature failure and ensures long-term performance of concrete elements.

3.2 Welded Wire Reinforcement (WWR) Design

The CRSI Manual of Standard Practice provides detailed guidelines for the design and application of Welded Wire Reinforcement (WWR), ensuring optimal performance in concrete structures. WWR consists of wire meshes or sheets fabricated into specific configurations, offering advantages in crack control and strength. The manual outlines material specifications, wire sizes, and spacing requirements to meet ASTM standards. Proper detailing and placement of WWR are emphasized to achieve desired structural behavior and durability.

Design considerations include load requirements, concrete cover, and environmental factors. The manual also addresses fabrication tolerances and inspection criteria to ensure compliance with industry standards, promoting efficient and reliable construction practices for WWR systems.

Fabrication and Placement of Reinforcing Steel

Fabrication involves cutting, bending, and assembling reinforcing steel to meet project specifications. Proper placement ensures structural integrity, with precise positioning and alignment in concrete forms.

4.1 Tolerances and Inspection Criteria

Tolerances for reinforcing steel placement ensure accuracy in construction. The CRSI manual specifies allowable deviations for bar placement, bending dimensions, and spacing to maintain structural integrity. Inspection criteria include verifying bar sizes, grades, and placement against project plans and specifications. Proper inspection ensures compliance with ASTM standards and project requirements. CRSI guidelines emphasize pre-pour inspections to identify and correct issues before concrete placement. Documentation of inspections is crucial for quality control and compliance reporting. Adhering to these standards minimizes defects and ensures durable, safe structures. Regular training for inspection personnel is recommended to maintain consistency and accuracy in the process.

4.2 Handling and Storage of Reinforcing Bars

Proper handling and storage of reinforcing bars are critical to maintain their quality and integrity. The CRSI manual emphasizes using suitable equipment and techniques to avoid bending or damaging the bars during transportation and placement. Bars should be stored on flat, elevated surfaces to prevent warping and exposure to moisture, which could lead to corrosion. Clear identification tags should be attached to each bundle for easy traceability. Regular inspection of stored bars ensures compliance with specifications and prevents the use of damaged materials. Adhering to these guidelines helps maintain project safety, reduces waste, and ensures the structural integrity of reinforced concrete elements. Proper storage conditions are essential for preserving the mechanical properties of reinforcing steel.

Durability and Protection of Reinforcing Steel

Durability and protection of reinforcing steel are crucial for ensuring the longevity and structural integrity of concrete structures. Environmental factors and corrosion risks must be addressed through proper protective measures and coatings, as outlined in CRSI guidelines.

5.1 Environmental Factors Affecting Reinforcing Steel

Environmental factors significantly impact the durability of reinforcing steel. Moisture, chlorides, and temperature fluctuations can lead to corrosion, weakening the steel and compromising structural integrity. Exposure to seawater, deicing salts, and industrial chemicals accelerates corrosion. The Manual of Standard Practice emphasizes the importance of assessing environmental conditions during design and construction. Proper concrete cover, surface treatments, and cathodic protection are essential to mitigate these effects. CRSI guidelines provide detailed recommendations for materials and practices to ensure long-term resistance against environmental degradation, safeguarding reinforced concrete structures from premature deterioration. Adhering to these standards is critical for maintaining the lifespan and safety of infrastructure.

5.2 Corrosion Protection Methods

Corrosion protection is vital for extending the lifespan of reinforcing steel. The Manual of Standard Practice outlines various methods to prevent or mitigate corrosion. Surface coatings, such as epoxy, create a barrier against corrosive substances. Cathodic protection systems, including sacrificial anodes or impressed current, redirect corrosion activity away from the steel. Concrete cover depth and quality are also critical, as they shield the steel from environmental factors. Additionally, corrosion-resistant steel alloys and galvanizing offer enhanced durability. CRSI recommends combining these methods based on environmental severity to ensure effective protection. Proper implementation of these strategies ensures structural integrity and reduces maintenance costs over time. Adherence to CRSI guidelines is essential for optimal corrosion management.

ASTM Standards and Compliance

CRSI’s Manual of Standard Practice aligns with ASTM standards, ensuring reinforcing steel meets rigorous specifications for materials, testing, and identification, promoting industry-wide compliance and quality.

6.1 ASTM Standards for Reinforcing Bars

ASTM standards provide critical specifications for reinforcing bars, ensuring consistency and quality in materials. The CRSI Manual of Standard Practice references ASTM standards like A615, A706, and A996, which cover chemical composition, mechanical properties, and testing methods for steel reinforcement. These standards ensure bars meet minimum requirements for strength, ductility, and durability. The manual emphasizes compliance with ASTM guidelines to maintain structural integrity and safety in concrete construction. By adhering to these standards, professionals can ensure reinforcing steel is suitable for various applications, from residential to large-scale infrastructure projects. CRSI’s alignment with ASTM standards underscores its commitment to industry excellence and reliability. Proper identification and certification of reinforcing bars are also addressed to prevent mismatches and ensure traceability. This section is vital for fabricators, engineers, and contractors to uphold quality and compliance in their work.

6.2 CRSI Recommendations for Identification Marks

CRSI provides detailed recommendations for identification marks on reinforcing steel to ensure traceability and compliance with industry standards. These marks typically include the producer’s identifier, grade, bar size, and type of steel. The Manual of Standard Practice emphasizes the importance of clear and legible markings to avoid confusion during fabrication and placement. Proper identification ensures that reinforcing bars meet specified material properties and ASTM standards. CRSI also advises on the placement and frequency of these marks to maintain consistency across projects. Adhering to these guidelines helps prevent errors and ensures that all materials are verified before use in construction. This section is essential for maintaining quality control and accountability in the supply chain.

References and Appendices

The manual includes appendices with tables, figures, and a glossary of terms, providing essential resources for design and construction professionals.

7.1 Tables and Figures for Design and Construction

The Manual of Standard Practice includes extensive tables and figures that provide critical data for designing and constructing reinforced concrete structures. These resources cover essential details such as development lengths, splice requirements, and reinforcement placement. Tables outline standard specifications for reinforcing bars, including dimensions, weights, and material properties. Figures illustrate proper detailing techniques, such as stirrup/tie hooks and bar bending details, ensuring compliance with industry standards. These visual aids and reference tables are invaluable for engineers, contractors, and fabricators, streamlining the design process and ensuring accuracy. They also include examples of standard reinforcement details, making it easier to apply best practices in the field.

7.2 Glossary of Terms and Definitions

The Manual of Standard Practice features a comprehensive glossary that clarifies technical terms and definitions commonly used in the reinforced concrete industry. This section ensures uniform understanding among professionals, from engineers to contractors, by providing precise definitions for terms like “development length,” “splice,” and “welded wire reinforcement.” The glossary also covers specific concepts related to materials, design, and construction practices, making it an invaluable resource for both novice and experienced practitioners. By standardizing terminology, the manual enhances communication and reduces misunderstandings, promoting consistency in the application of industry standards and best practices. This ensures that all stakeholders are aligned in their understanding and implementation of reinforcing steel techniques.